News & Events

Washington Penn Sees Growing Demand for PP Compounds in HVAC Diffusers

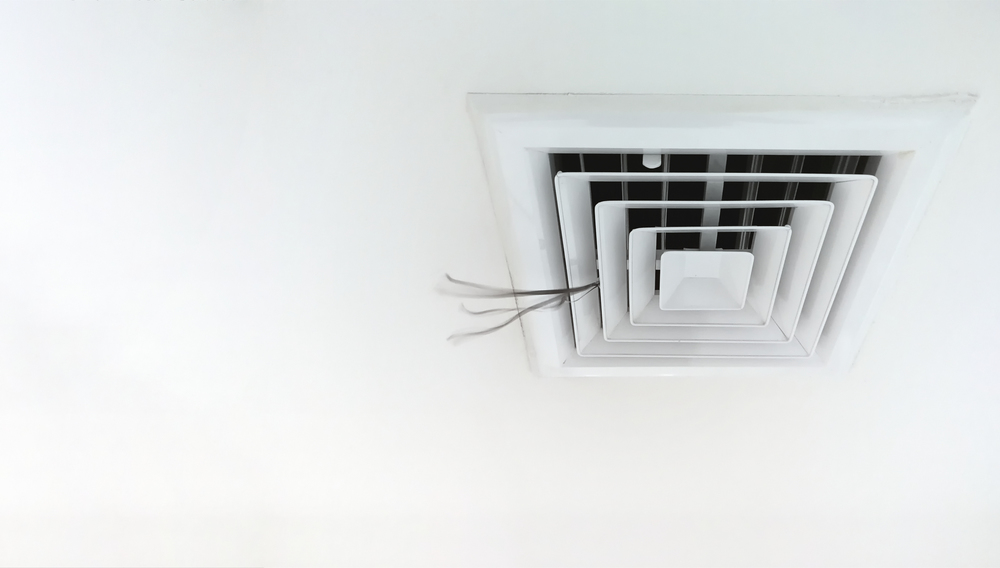

Washington Penn, a leading global supplier of engineered polyolefin compounds, is witnessing a growing trend in the use of engineered polyolefins as a metal replacement option for HVAC diffusers in the commercial and residential construction market. The company provides OEMs with highly engineered polypropylene (PP) compounds that deliver lightweight, enhanced durability, rust resistance, and scratch and mar resistance.

The trend is firmly in place in Europe where HVAC manufacturers are moving to more environmentally friendly alternatives such as non-halogenated flame retardant (FR) versions of PP.

“Manufacturers in the HVAC market are looking to update their designs by using customized PP compounds that provide greater cleanliness, high performance, and lasting aesthetics compared to traditional materials such as aluminum,” said Adia Delaney-Jackson, National Account Manager for Washington Penn.

In certain commercial applications like restaurants and other business establishments, a cost-effective approach is to develop an upgraded plastic design rather than continually refurbishing or replacing metal or aluminum units. Plastic air vents won’t rust or corrode and scratches won’t be visible because the color is molded throughout the unit, not just painted on the surface. PP grades are mildew-resistant, resist sweating, and are not easily damaged if dropped. They are also commercial dishwasher safe. PP is also a styrene-free option versus other thermoplastic alternatives such as acrylonitrile-butadiene-styrene (ABS).

The company’s mineral-reinforced PP compounds are designed to meet individual customer requirements. They are injection molded for a range of diffuser applications.

Washington Penn's custom solutions can also contain recycled-content, flame retardant (FR) additives, Ultra Violet (UV) stability, scratch & mar resistance, and are available in a broad range of colors and unique finishes.